Overview

Traditionally, biomass such as corn and non-food mass such as switchgrass is converted into transportation fuel (e.g., ethanol, bio-diesel) using biological and thermochemical approaches. Non-food biomass can be either gasified to produce synthesis gas (syngas), or subject to fast pyrolysis to produce liquid bio-oil. Fischer-Tropsch synthesis is performed on syngas to produce transportation fuel. The process of producing transportation fuel and syngas from biomass gasification is an established and mature technology. However, commercialization of biomass gasification is hindered by a number of issues such as capital/operating costs, difficulties transporting solid biomass over long distances, and contaminant removal from product gas stream. A feasible but lesser studied alternative is to gasify bio-oil to syngas, after fast pyrolysis, which can then be synthesized into liquid transportation fuel. This approach potentially addresses the above listed difficulties with biomass, but a commercial viability of this approach was never determined.

To determine the feasibility at a commercial level, it is cost effective to develop numerical approximation models (metamodels) built off limited physical laboratory experiments or numerical simulations and then scale appropriately to determine the cost to benefit ratio in a commercial setting. This project presents the work done in building various metamodels to characterize actual bio-oil gasification. Syngas outputs were computed in real-time using pre-built metamodels. The results from using metamodels were in close comparison with results from experimental and numerical simulations. Also, a visual interface was built that not only incorporates generating syngas outputs using metamodels, but also lets the user create, edit, and visualize bio-oil gasification facility geometries regardless of whether it is a laboratory scale, or a commercial scale on both desktop and 3-D immersive stereoscopic environments.

Methodology

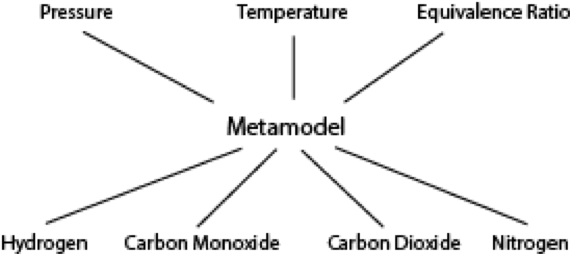

Three different metamodel schemes were used to calculate the pressure, temperature, and equivalence ratios: Polynomial Response Surface (PRS), Radial Basis Functions (RPF), and Kriging. PRS approximations are designed to approximate datasets using polynomial expressions. RBF is a technique for defining a smooth function that interpolates a set of function values specified at an arbitrary set of data points and is best used in multivariate scattered data interpolation. Kriging is an interpolation methodology based on Gaussian processes governed by prior covariances that is not only able to produce an estimate of a function, but an estimate of the error as well. The creation of the metamodels provided a 95 percent accuracy when mapping inputs to the experimental output values of hydrogen, carbon monoxide, carbon dioxide, and nitrogen.

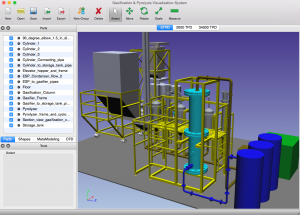

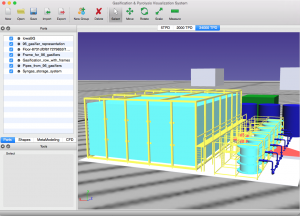

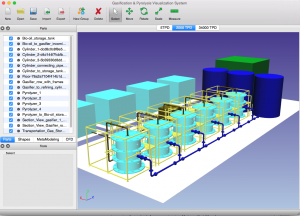

The creation of the metamodels not only produced a high accuracy but also decreased the calculation time from 1.5 hours to real-time. The metamodels were produced with a set of 125 known combinations generated from simulations conducted at Iowa State University. Implementing the metamodels allowed for the development of a 3D viewer to analyze different scenarios that syngas and transportation fuel could be produced from the biomass gasification. The first image shows the 3D viewer of a pilot plant that produces 5 tons per day (TPD). The second image shows a standalone facility with a 2,000 TPD capacity. The third image shows a commercial scale facility with a 34,000 TPD capacity.