Today, we continued our deeper dive into 3D printing. I learned about several things about how to print properly.

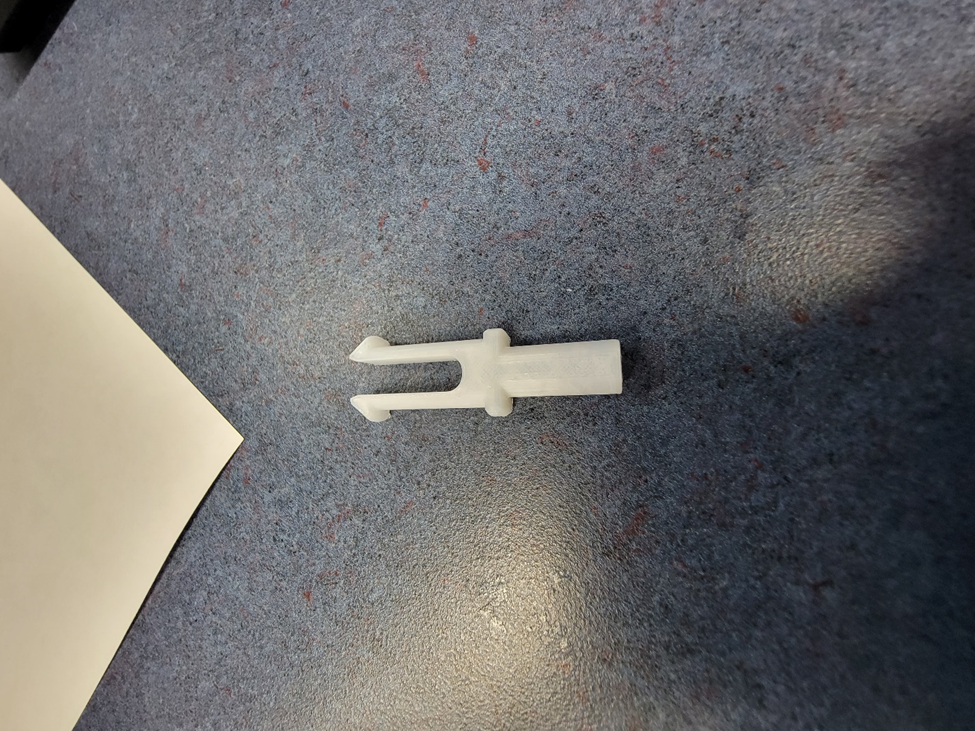

This morning, we observed the printing of a small 3D part. Over the course of the printing process, I was interested in the defects on the corners and how infill patterns affect the strength of the printed object. As I asked about the issue of infill patterns, Alex found a paper by Alafaghani et al. (2017), which found that there was little difference between each type of infill patterns. However, this paper only tested one shape of tensile bar, one printer, and one type of filament. Thus, predicting the strength of 3D printed materials with regards to infill type remain difficult.

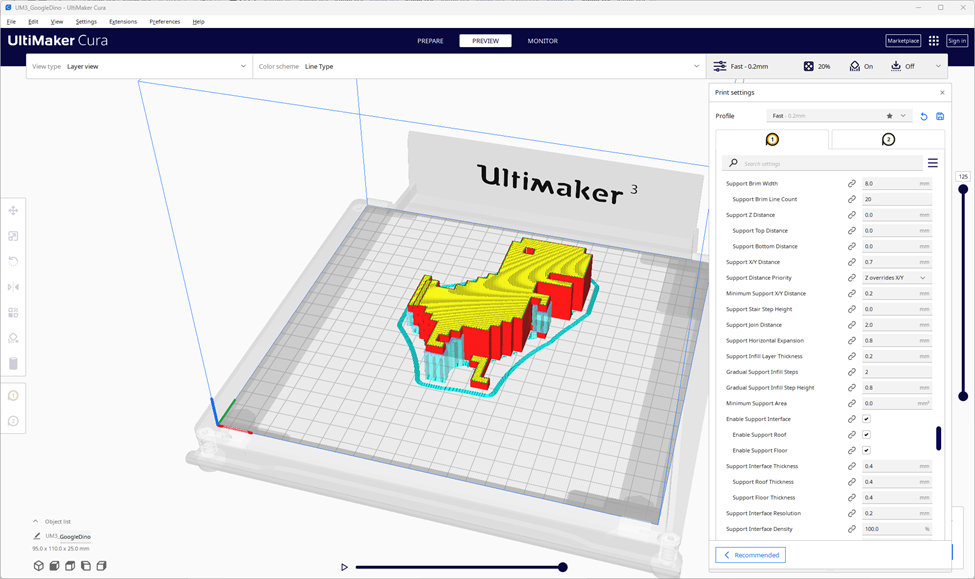

Later this afternoon, we discussed how 3D printing can solve specific problems that other forms of manufacturing can pose a challenge. For example, we can embed other items into an object by pausing printing and inserting that. We could insert a metal thread into a hole, for instance, or we could even embed wires as well. We also talked about how supports work, which might be needed when an overhang exceeds 45 or 65 degrees.

While I was thinking about these challenges, Alex told us we were able to print an object that will help us towards building our MCAs. I decided to print this Chrome Dino from Thingiverse (https://www.thingiverse.com/thing:5977565/files). This model allows me to observe several properties of 3D printing I learned. For example, the square edges allows me to observe defects when printing on the corners, the shape allows the heavy usage of infills, and the overhangs require the use of supports which I will need to remove after the printing process.